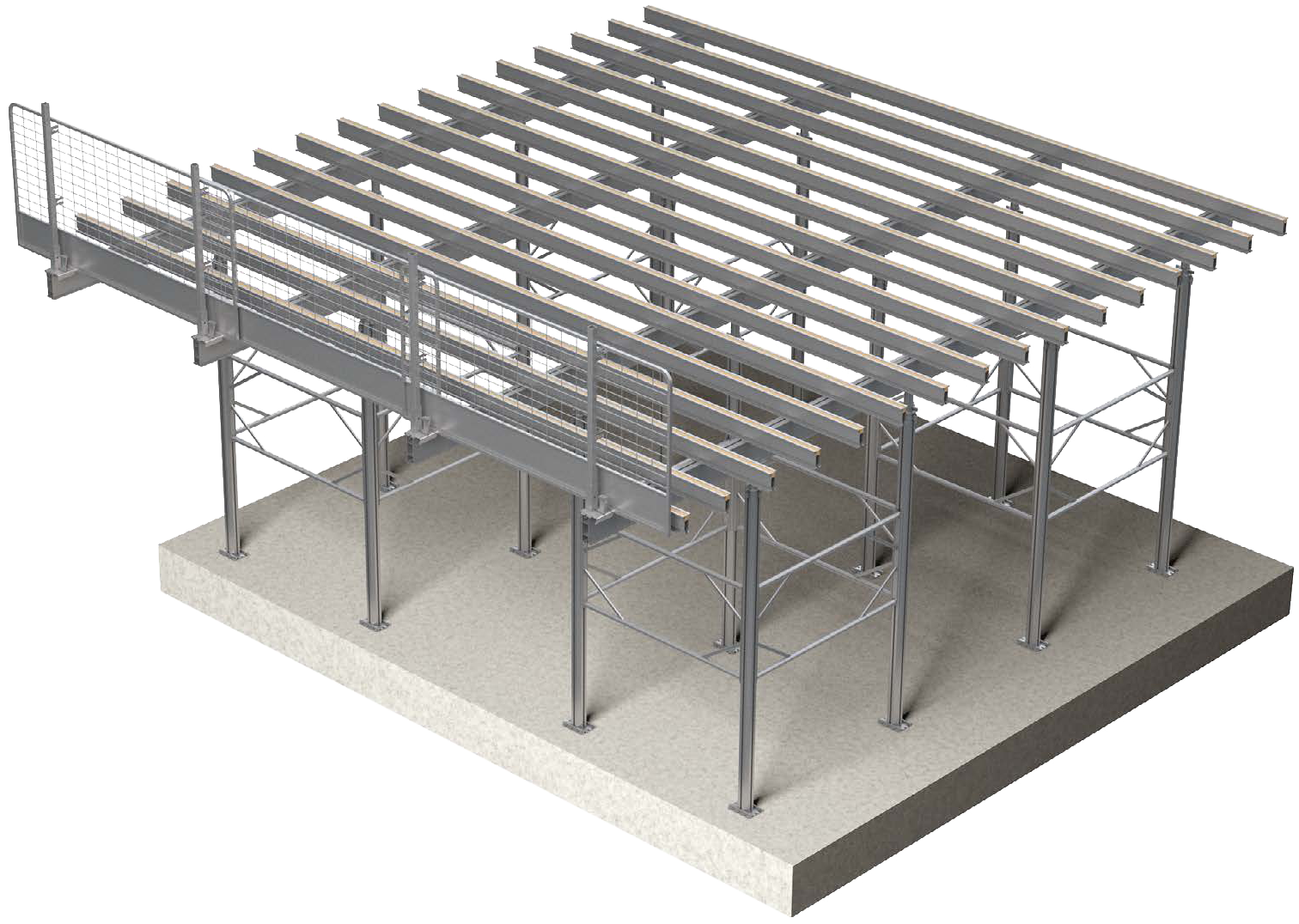

TITAN Support System

Westport Equipment is proud to be the hire partner for The Titan Support System, recognised as the leading product in its field by many professionals in the construction and civil engineering industries. Comprising two main components: legs and frames, together with a comprehensive range of accessories, the Titan Support System offers one of the quickest, most effective and versatile means of providing rapid support and access solutions in a wide variety of situations.

The system can be used in both ‘flying table’ and erect and dismantle applications and is ideal for multi-storey structures, water reservoirs and soffit situations where mobility and ease of handling are required. With the majority of components being manufactured from high-grade aluminium to patented designs, the Titan support system possesses an exceptionally high strength-to-weight ratio which facilitates rapid erection, whilst its excellent corrosion resistance and robust build quality assure long-term durability. The Titan support system is designed to reduce labour costs, increase site efficiency, improve safety and meet the demands of today’s construction and civil engineering techniques.

The system has many benefits:

Manufactured from extruded aluminium section, TITAN beams offer a lightweight, easy to handle solution for decking/soffit applications.

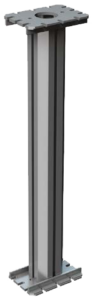

Extension pieces are available to make up non-standard heights.

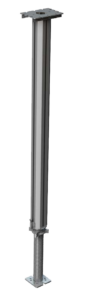

Available in five sizes, each with continuous vertical slots to allow ledger frames to be fitted quickly and securely at the optimum height.

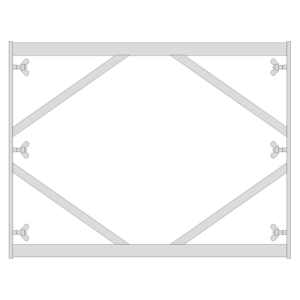

A range of seven ledger frames is available.

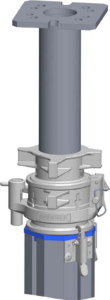

TITAN Strike makes easy work of striking and stripping TITAN legs, especially at high load levels and in noise sensitive areas. Quicker and less impactful on equipment and your team, TITAN Strike makes an efficient and economical addition to the TITAN Support system.

The system has many benefits:

Manufactured from extruded aluminium section, TITAN beams offer a lightweight, easy to handle solution for decking/soffit applications.

A range of seven ledger frames is available.

TITAN Strike makes easy work of striking and stripping TITAN legs, especially at high load levels and in noise sensitive areas. Quicker and less impactful on equipment and your team, TITAN Strike makes an efficient and economical addition to the TITAN Support system.

MAKE A HIRE ENQUIRY

Please submit an enquiry below. One of our team will contact you to discuss your requirements. Please note: You must have an account with Westport Equipment to hire this equipment.

* = required fields

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

TITAN Support erection sequence:

1.

Connect the ledger frame horizontally between two legs. Predetermined ledger frame position measured from the head plate

2.

Connect ledger frame vertically to leg

3.

Repeat 2 to form three sides to bay

4.

Repeat 1 to form 4th side of bay and then lift both sides of bay into position

5.

Connect both sides to form a four leg tower

6.

Now add additional frames and legs to form TITAN support structure

7.

Place intermediate transoms and scaffold boards or walkway platforms and handrail frames in position for fixing TITAN aluminium beams

8.

Fix primary beam to head plate by means of two TITAN clamps

9.

Position secondary beams and fix them with a TITAN clamp at each intersection with a primary beam. The structure is now ready for fixing of plywood