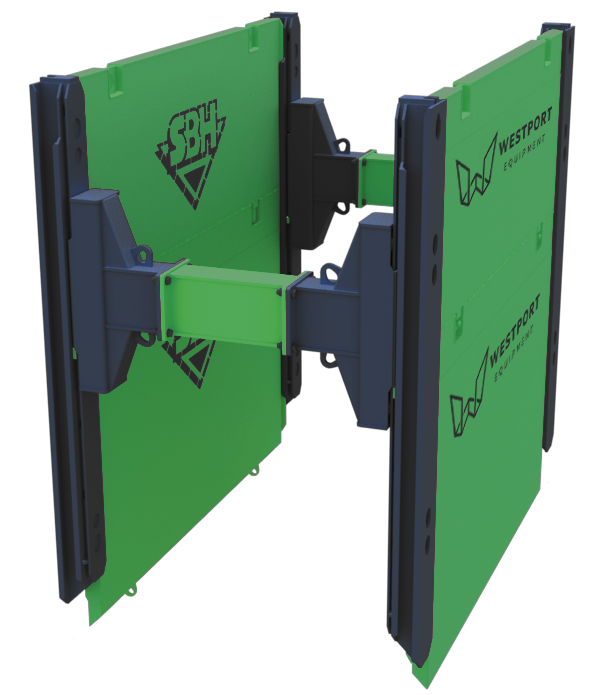

Slide Rail Shoring

In the case of slide rail shoring with roller carriages, the individual shoring components are only completed in the trench to form a closed shoring wall.

Plates, RS carriers and roller carriages can be moved parallel to one another. The trench remains the same width at all times during the construction phase. This significantly reduces the forces to be applied during installation and dismantling. There are fewer vibrations and the shoring itself has very little settlement.

The H-shaped design of the roller carriage offers optimal conditions in all work phases. During the installation phase, the roller carriage is located in the lower area of the beam, giving the excavator driver a clear view and working with a short boom.

Another advantage is the large pipe passage heights, which can also be continuously adjusted while the pipe is being laid. The required working width is realised using spacers. Depending on the depth of the trench, roller carriage systems with single, double or triple guided plate levels are available to the customer.

Single Slide Rail

Recommended upto 3.8m

Double Slide Rail

Recommended upto 8.5m

2M

3M

4M

5M

6M

7M

8M

9M

1M

2M

3M

4M

5M

6M

7M

8M

9M

Advantages Of The Slide Rail System

- No piling hammer requirements

- No trench sheet damage charges

- No vibration issues

- No hydraulics

- No early entry requirements, to install hydraulic frames

- The number of lifting operations reduced

- Accelerated programme / lower costs