Fast Track to Success: How Westport Equipment Helped Des Nally Developments Deliver Record-Breaking Trench Shoring Efficiency

In the world of civil construction, time is often the most unforgiving constraint. For Des Nally Developments, that challenge came to a head at a congested junction near a major motorway exit, where the company was tasked with installing an ESB joint bay in a tight window – both in terms of space and schedule. The result? A best-in-class demonstration of what happens when the right contractor partners with the right equipment supplier.

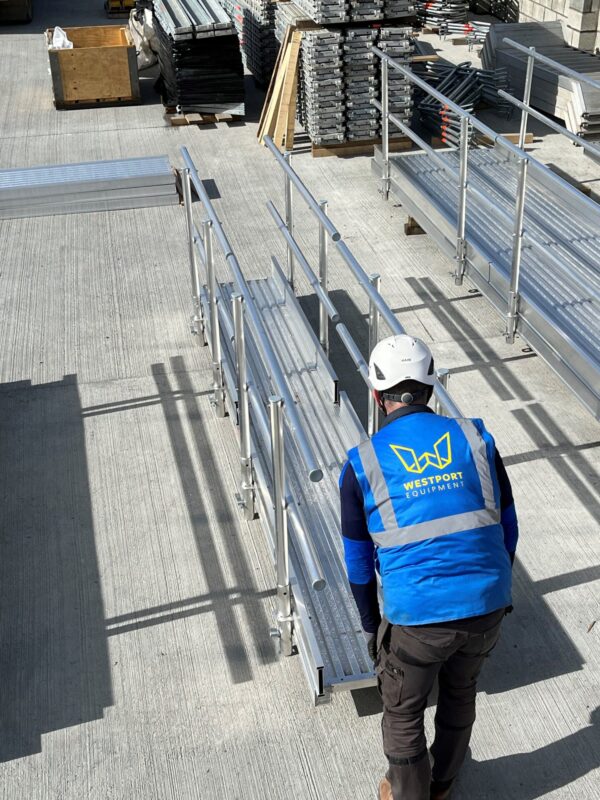

At the heart of this was a single slide rail pit measuring 3.4m x 7.6m x 2.55m deep. While that might seem straightforward on paper, the logistical complexity of shoring in such a busy location—and doing it safely, quickly, and without compromise—required a high-performance solution. Enter Westport Equipment.

The Right Call at the Right Time

Following technical discussions with Ruairi O’Neill at Westport Equipment, Des Nally Developments made the strategic decision to abandon traditional sheet piling in favour of a more agile and efficient approach: a single slide rail shoring system. The outcome was transformative.

“The slide rail was delivered Wednesday afternoon and off-site by Thursday evening. That 24-hour turnaround simply wouldn’t have been possible with sheet piling,” said James Carey of Des Nally Developments.

In fact, a conventional sheet-piled installation of the same dimensions would typically take between three to four days, depending on soil conditions and site complexity. The slide rail solution not only slashed the installation time, it also eliminated the need for excessive excavation and backfill work—streamlining operations and mitigating disruption in a high-traffic zone.

Built on Engineering Precision

Behind the speed was meticulous engineering. Westport Equipment provided a full suite of temporary works designs, complete with detailed structural drawings and verified calculations to ensure site safety and compliance from start to finish. The result was a robust, stable, and secure excavation environment that prioritised crew safety as much as project speed.

“We had the reassurance of a complete engineering package, which meant our teams could focus on doing the job right – without second-guessing the stability of the system,” Carey added.

Trust Built Over Time

While this installation may have set new internal records for Des Nally Developments, the collaboration with Westport Equipment was no one-off. The relationship between the two firms has grown over the past year, built on consistent performance and responsive support.

“Every time we use Westport’s kit, we know we’re getting dependable, high-quality equipment with service to match. It’s that reliability that keeps us coming back,” Carey concluded.

Shaping the Future of Shoring

In an industry where productivity gains are hard-earned and rarely guaranteed, the successful deployment of slide rail shoring at this scale is a testament to what’s possible when contractors embrace innovation and align with supply partners who understand the demands on site.

Des Nally Developments’ rapid installation wasn’t just a project milestone—it was a signal to the broader construction sector: modern shoring systems like slide rail aren’t just alternatives to traditional methods. They’re the future.